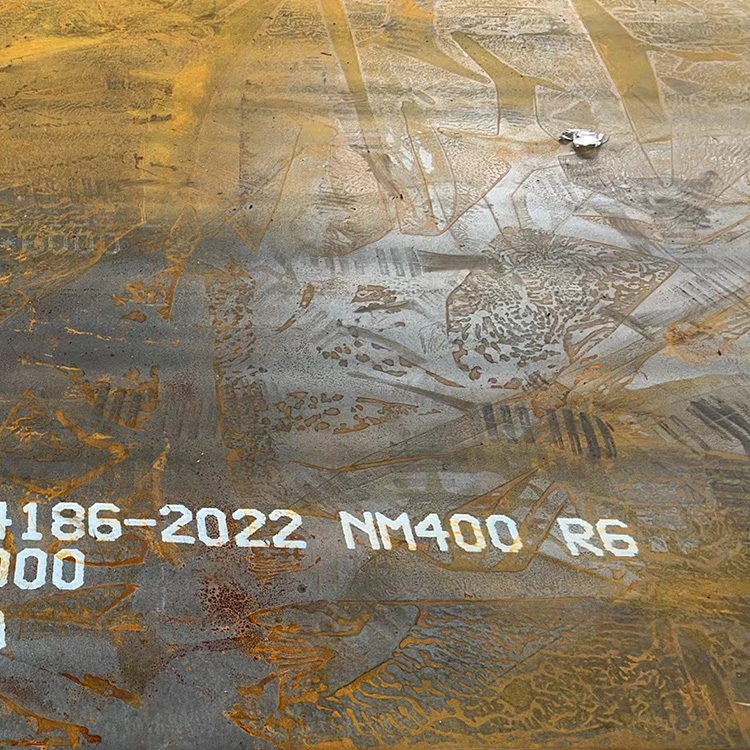

Main products

What are the influencing factors of the hardness of wear-resistant steel NM400?

- TEL/WeChat:+86 13928292816

- Email:Pengbingan01@gmail.com

There are several factors that affect the hardness of wear-resistant steel NM400.

Chemical composition: Carbon content: Carbon is one of the key elements affecting the hardness of NM400 wear-resistant steel. A higher carbon content can improve the hardness and strength of steel, but excessive carbon content may lead to a decrease in toughness and an increased risk of brittle cracking. For example, when the carbon content increases within a certain range, the hardness of NM400 wear-resistant steel will correspondingly increase. The addition of alloying elements such as chromium, molybdenum, and manganese can also affect hardness. Chromium can improve the hardenability and wear resistance of steel; Molybdenum can refine grain size, improve the strength and hardness of steel; Manganese can increase the strength and toughness of steel. The reasonable combination of these alloying elements can ensure hardness while also considering other properties of the steel.

Heat treatment process: Quenching: Quenching is an important heat treatment process to improve the hardness of NM400 wear-resistant steel. By rapid cooling, the structure of steel undergoes transformation, forming higher hardness structures such as martensite, thereby increasing the hardness of the steel. For example, under appropriate quenching process parameters, the hardness of NM400 wear-resistant steel can reach a high level.

Tempering: Tempering is a heat treatment process carried out after quenching, with the aim of eliminating quenching stress and improving the toughness and stability of steel. The selection of tempering temperature and time has a certain impact on the hardness of NM400 wear-resistant steel. If the tempering temperature is too high or the tempering time is too long, it may lead to a decrease in hardness; On the contrary, if the tempering temperature is too low or the tempering time is too short, the quenching stress cannot be fully eliminated, which may affect the performance of the steel.

- Previous article:What is the development trend of wear-resistant steel NM400 ?

- Next article:NM400 wear-resistant steel plate Brinell hardness range