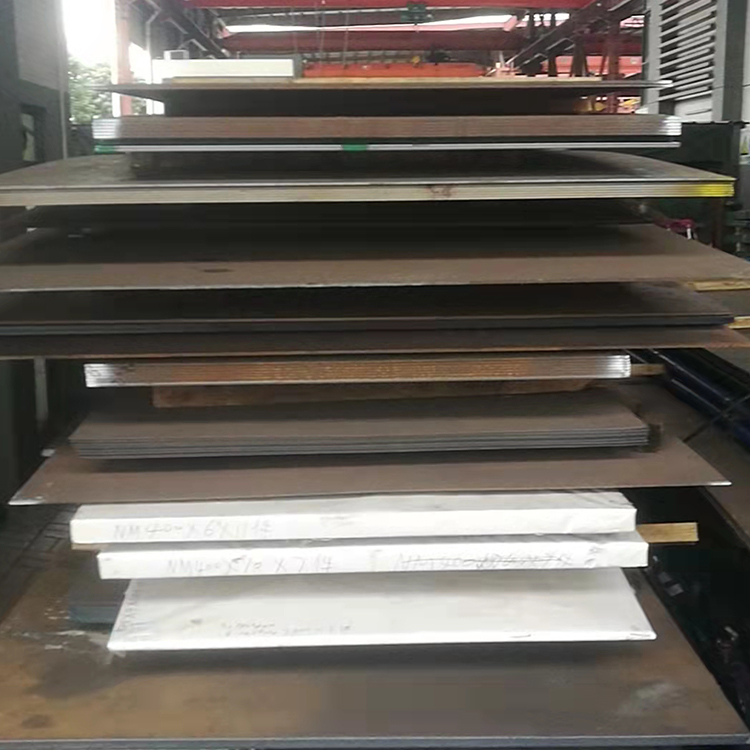

Main products

What is the development trend of wear-resistant steel NM400 ?

- TEL/WeChat:+86 13928292816

- Email:Pengbingan01@gmail.com

Higher strength and hardness: With the large-scale and efficient development of equipment in the building materials industry, the requirements for the load-bearing capacity and wear resistance of wear-resistant components are constantly increasing. In the future, the strength and hardness indicators of NM400 wear-resistant steel will be further improved through improving smelting processes and optimizing alloy composition, so that it can better cope with high load wear conditions and extend the service life of key equipment components such as crusher hammers, jaw plates, and conveying pipelines.

Research more advanced heat treatment processes to make the metallographic structure of wear-resistant steel more uniform and dense, thereby fully utilizing the material's performance potential and improving its wear resistance and strength without increasing excessive costs.

Better toughness and impact resistance: In the production process of building materials, equipment components not only have to bear the wear and tear of materials, but also are often subjected to impact loads. In order to reduce the cracking and damage of wear-resistant components under impact, NM400 wear-resistant steel will further improve its toughness and impact resistance while maintaining a certain hardness in the future.

For example, by adjusting the content of carbon, manganese and other elements and adding specific alloy elements, the comprehensive mechanical properties of the material will be optimized to make it both wear-resistant and able to withstand large impact forces, adapting to the working environment of equipment such as stone crushers and vibrating feeders in quarries .Develop new material processing technologies, such as microalloying and controlled rolling and cooling, to improve the microstructure of wear-resistant steel, achieve a better balance between strength and toughness, and enhance the impact wear resistance of materials.