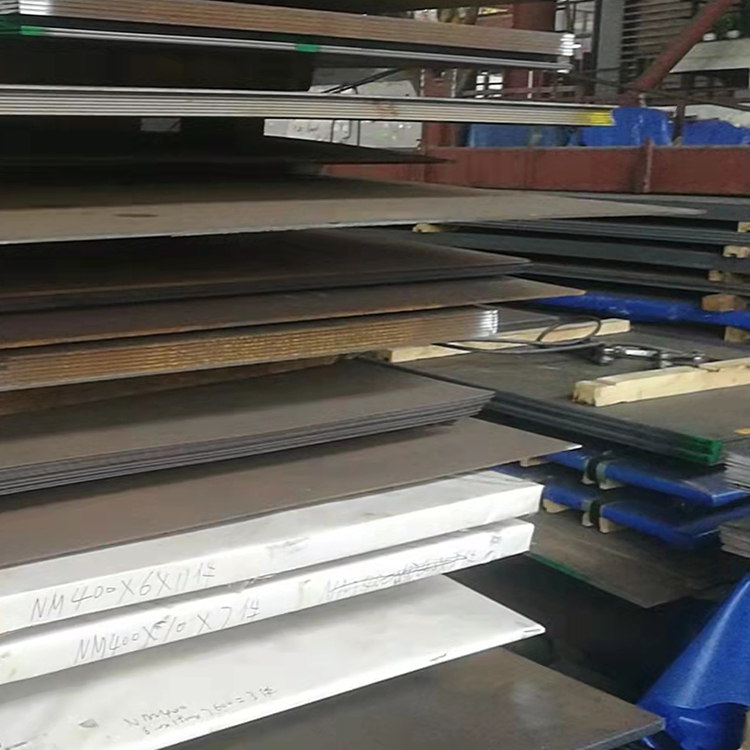

Main products

How to choose the appropriate wear-resistant steel grade?

- TEL/WeChat:+86 13928292816

- Email:Pengbingan01@gmail.com

Choosing the appropriate wear-resistant steel grade can be considered from the following aspects:

Abrasive wear: If the working environment is mainly abrasive wear, such as mines, quarries, etc., it is necessary to choose wear-resistant steel grades with high hardness and good wear resistance. For example, high-strength wear-resistant steels such as NM400, NM500, NM550, and NM600 can effectively resist the cutting and impact of abrasives, extending the service life of equipment.

Impact wear: In some working environments, equipment may be subjected to significant impact loads, such as crushers, vibrating screens, etc. At this point, it is necessary to choose wear-resistant steel grades with good toughness and impact resistance. For example, medium strength wear-resistant steels such as NM400 and NM450 have good toughness while ensuring a certain hardness, and can withstand impact loads without fracture.

Corrosion and wear: In some corrosive working environments, such as chemical and marine fields, it is necessary to choose wear-resistant steel grades with good corrosion resistance. Wear resistant steels with added alloying elements such as chromium and nickel, such as NM400Cr, NM500CrNi, hiace, etc., can be selected. These grades of wear-resistant steels not only have good wear resistance, but also resist the erosion of corrosive media.

Working temperature: If the working environment temperature is high, it is necessary to choose wear-resistant steel grades with good heat resistance. For example, heat treatment equipment and cement kilns working in high-temperature environments can choose heat-resistant and wear-resistant steels such as NM400H and NM500H. These grades of wear-resistant steels can still maintain high hardness and strength at high temperatures and have good wear resistance. If the working environment temperature is low, it is necessary to choose wear-resistant steel grades with good low-temperature toughness. For example, construction machinery and mining equipment working in cold regions can choose low-temperature wear-resistant steels such as NM360LT and NM400LT. These grades of wear-resistant steels can maintain good toughness at low temperatures and preventbrittle fracture.