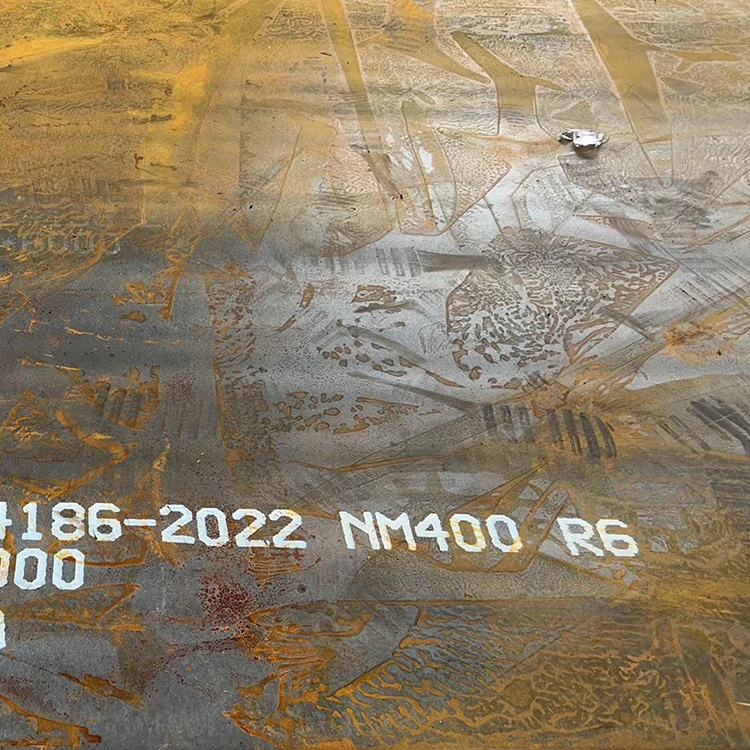

Main products

Factors affecting the strength of NM400 wear-resistant plate

- TEL/WeChat:+86 13928292816

- Email:Pengbingan01@gmail.com

The following are the factors that affect the strength of NM400 wear-resistant plate:

1、 Chemical composition An increase in carbon content can improve strength, but toughness may decrease. Alloy elements such as chromium, manganese, molybdenum, nickel, etc. can enhance strength and wear resistance.

2、 Production process In the smelting process, purity control and alloy element addition affect strength. The temperature, reduction amount, and other parameters of the rolling process affect the strength and uniformity of the microstructure. Heat treatment processes such as quenching and tempering can adjust strength and toughness.

3、 Microstructure Fine grain size, reasonable phase composition, and uniform distribution of carbides can improve strength

- Previous article:How to choose the appropriate heat treatment process for NM400 wear-resistant plate?

- Next article:Wear resistant steel picture