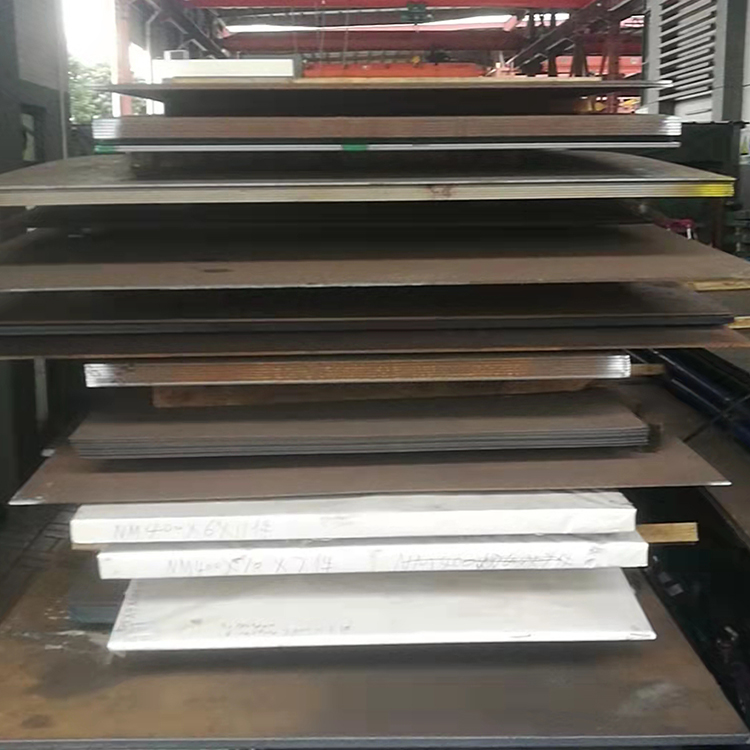

Main products

How to choose the appropriate heat treatment process for NM400 wear-resistant plate?

- TEL/WeChat:+86 13928292816

- Email:Pengbingan01@gmail.com

According to the usage scenario of NM400 wear-resistant plate, the selection of heat treatment process can be considered from the following aspects:

1、 Wear and tear condition Choose quenching and tempering for high wear scenarios to improve hardness, strength, and wear resistance. Moderate wear can be treated with normalizing and tempering to refine grain size and balance strength and toughness. Annealing can be considered for low wear scenarios to reduce hardness and facilitate processing.

2、 Impact load Quenching and high-temperature tempering are used for high impact loads to improve toughness and prevent fracture. Choose quenching+medium temperature tempering for moderate impact load. Low impact load can be selected as normalizing or annealing according to requirements.

3、 Temperature conditions Choose quenching+tempering+high-temperature tempering for high temperature scenarios to ensure high temperature strength and oxidation resistance. Select appropriate processes based on wear and impact in normal temperature scenarios. Quenching and low-temperature tempering are used in low-temperature scenarios to improve low-temperature toughness.

4、 Cost and efficiency Taking into account both cost and production efficiency, choose a heat treatment process that is cost-effective and meets the production schedule.