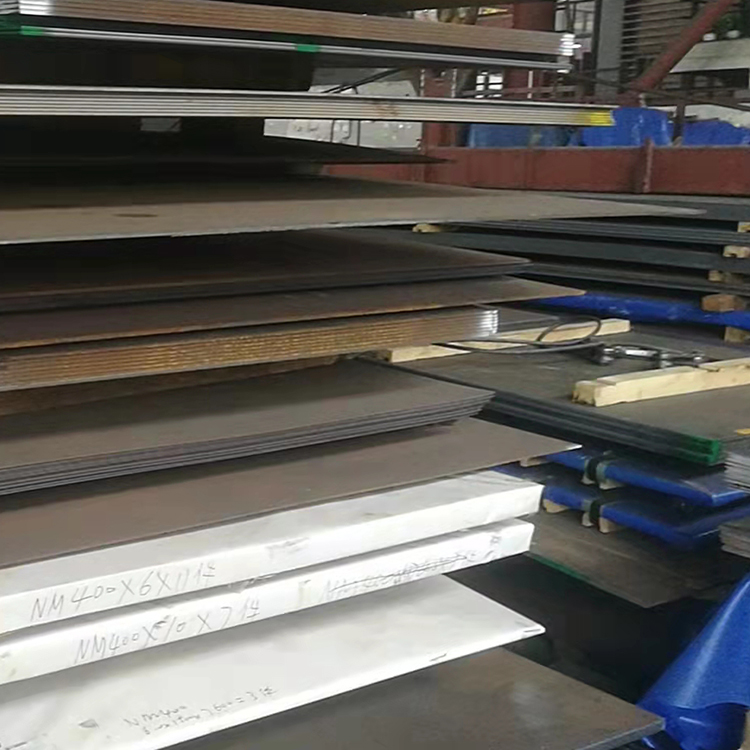

Main products

What factors affect the toughness of NM400 wear-resistant steel?

- TEL/WeChat:+86 13928292816

- Email:Pengbingan01@gmail.com

The main factors affecting the toughness of NM400 wear-resistant steel are:

1、 Chemical composition Carbon content: Excessive carbon content can reduce toughness. Alloy elements: such as manganese can improve toughness, and a reasonable ratio of alloy elements can balance hardness and toughness.

2、 Heat treatment process Quenching temperature and cooling rate: too high or too fast will reduce toughness. Tempering temperature and time: Proper tempering can improve toughness.

3、 Microstructure Grain size: Fine grains have good toughness. Organizational morphology: Bainite, tempered martensite and other microstructures have good toughness.

4、 Processing technology Rolling process: Reasonable rolling can improve toughness. Welding process: It affects the toughness of welding joints and requires the use of appropriate processes to reduce brittle structures.

5、 Usage environment Temperature: Low temperature is brittle, and high temperature also affects toughness.Corrosive medium: will reduce toughness, anti-corrosion measures need to be taken.